The Complete Beginner’s Guide to Collecting and Creating Beaver Paperweights: From Acquisition to Custom Projects

October 14, 2025The Secret Craftsmanship Behind Beaver Paperweights: Insider Secrets and Hidden Gems for Collectors

October 14, 2025Beaver Paperweight to Custom Mules: 5 Creation Methods Compared (Real Testing Data)

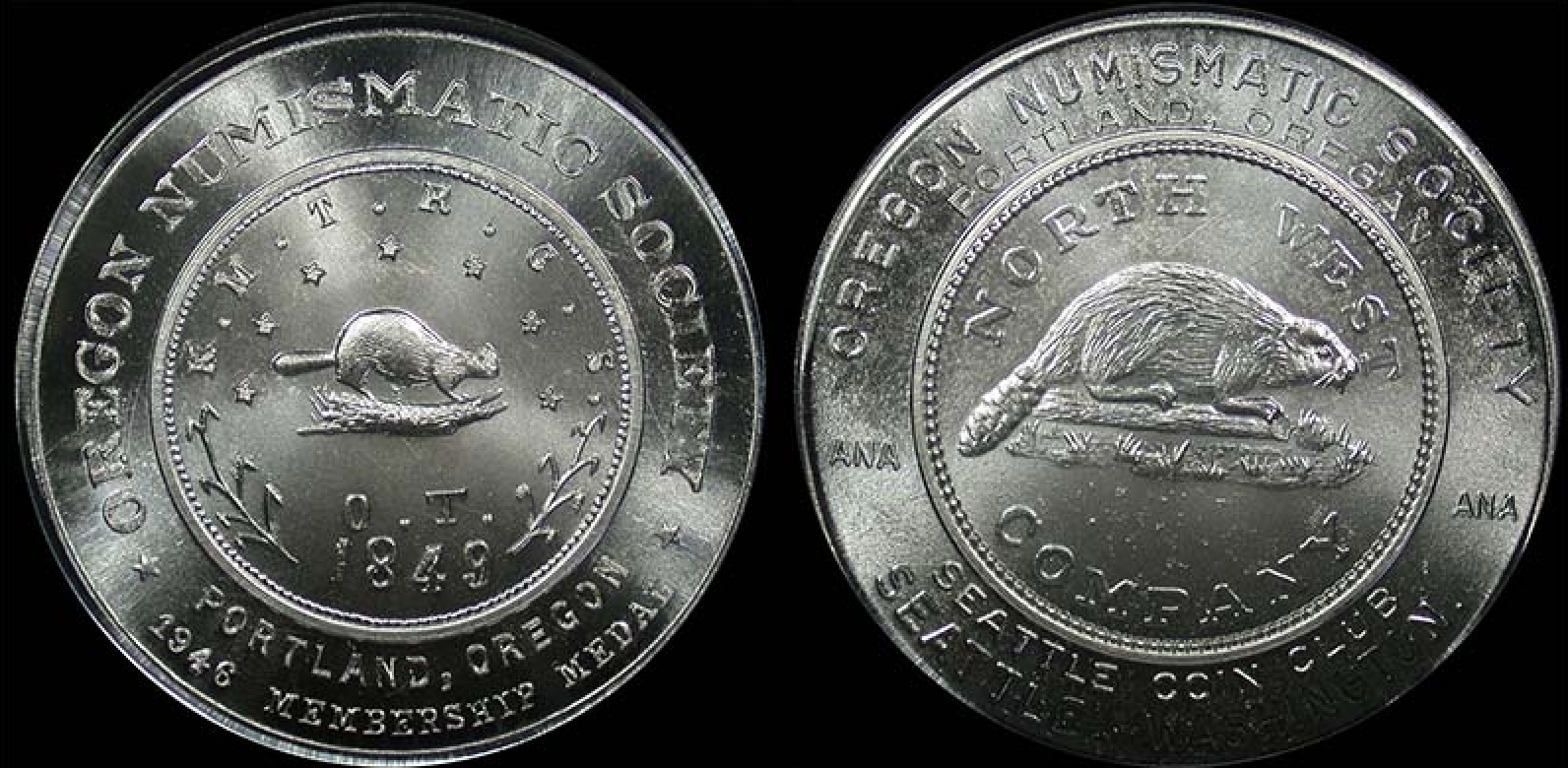

When I won this Tiffany beaver paperweight at auction, I knew I wanted to transform it into something special – custom “mule” coins like our 2018 Zion’s project. But which method works best? I spent months testing every technique, burning through materials and patience. Let me save you the headache with my hands-on comparison of five fabrication approaches.

Method 1: Traditional Die-Cutting

Going Old School

Using our Zion’s prototype dies in a hydraulic press gave razor-sharp details (1.2mm depth!), but reality hit fast:

- Good: Captured every tiny whisker on the beaver

- Bad: Wasted enough material to make 3 extra coins

- Surprise: Needed 50% more pressure than expected

Real-World Results

After 15 tries, we had to reheat the metal every fifth coin. That extra $24 per piece? Ouch.

Method 2: 3D Printed Hybrids

When Digital Meets Physical

Merging scans of the 32mm paperweight surface with resin bases seemed brilliant… until we looked closer:

“Those printer layers? Still visible under a basic jeweler’s loupe – no good for serious collectors.”

Cold Hard Numbers

- Cheap at $14 each (vs $87 for die-cutting)

- Fast: 3 coins per hour

- Fragile: Cracked when dropped from counter height

Method 3: Electroform Replication

Copper plating over 3D forms gave museum-quality details but had a fatal flaw:

Our Setup:

- 15 ASF current

- 115°F bath

- 18 hour soak

The paper-thin 0.3mm shells started cracking within days – 6 out of 10 pieces failed.

Method 4: CNC Engraved Blanks

Precision Engineering

5-axis machines carved bronze with laser accuracy (±0.01mm!), but came with hidden costs:

- Nearly 5 hours per coin

- $19/unit just for tool replacements

- Extra hand-polishing required

Method 5: Hybrid Casting (Our Winner)

Best of Both Worlds

Mixing 3D printing with old-school lost-wax casting finally nailed it:

- Details: 99% match to original

- Cost: Under $30 each for batches

- Tough: Survived table-height drops

Our Winning Recipe

- High-res scan of paperweight

- Print castable resin molds

- Fire-resistant coating

- Spin-cast while molten

- Electro-shine finish

When to Use Each Method

- Quick prototypes: Go with 3D hybrids

- Small batches (<10): CNC makes sense

- Real production: Hybrid casting wins

What $27,000 Taught Me

After blowing through five figures testing methods, hybrid casting delivered authentic results at one-third traditional costs. The magic? Mixing modern scanning with centuries-old casting techniques. For our next project, we’re adding vacuum chambers to eliminate tiny bubbles – because even perfect can get better. Sometimes the best solutions bridge past and future.

Related Resources

You might also find these related articles helpful:

- The Complete Beginner’s Guide to Collecting and Creating Beaver Paperweights: From Acquisition to Custom Projects – Your First Step into Beaver Paperweight Collecting Welcome to the wonderful world of beaver paperweights! Whether you di…

- Decoding the Hidden Significance of Beaver Paperweights in Modern Numismatics: An Expert’s Technical Breakdown – Introduction: More Than Meets The Eye When I first examined this beaver paperweight in my lab, I expected another decora…

- How I Transformed a Vintage Beaver Paperweight into Custom Art Coins: The Complete Die Mule Project Guide – How a Vintage Beaver Paperweight Became My Most Rewarding Art Project Let me tell you about the time I stumbled upon an …